The woodworking industry relies on these machines to rapidly mass produce products ranging from door panels to structural framing for cabinets. A prominent byproduct within the industry is sawdust.

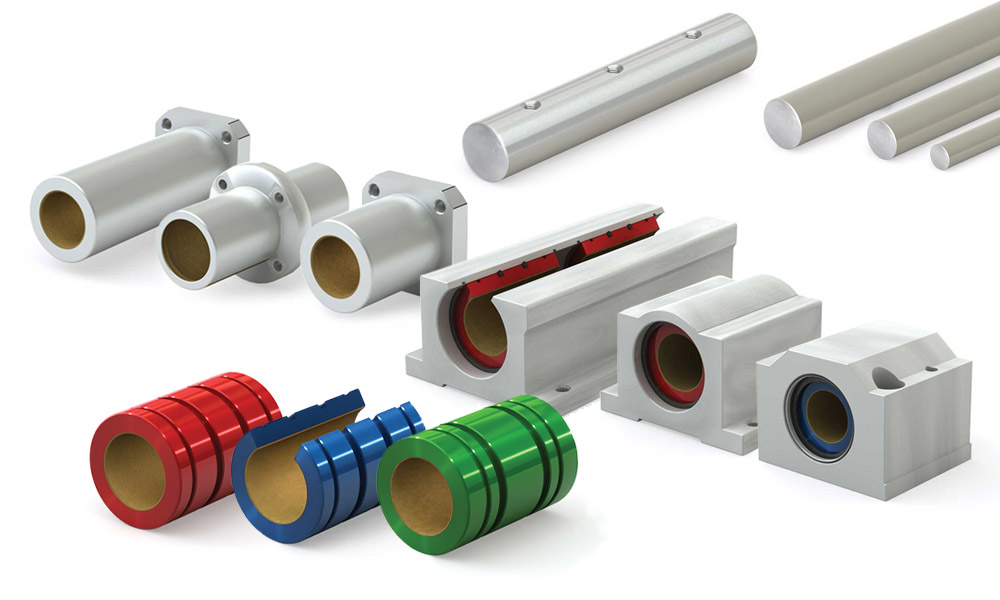

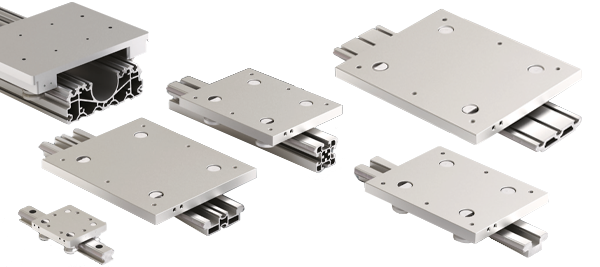

Cost-Saving, High Performance Linear Motion Solutions

PBC Linear designs and manufactures linear motion components and complete XYZ systems ideal for bio-sample handling and lab automation applications. From simple to complex maintenance-free components, all the way to sophisticated Cartesian robotic and automation systems, PBC’s products ensure long-lasting operation, enhanced system performance, and lower total installed cost.

The focus is on: