Belt drive or lead screw? The answer is in the application

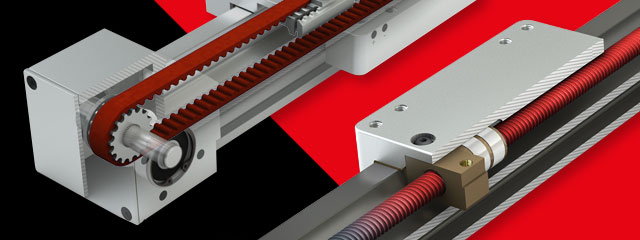

Engineering advancements in the field of linear motion have generated several options for driven actuator systems. Two of those types of drive systems that are essential to converting rotary motion into linear motion include the belt drive and lead screw. Both options have a unique role to play within actuator systems.

There are many important parameters to consider when choosing between a belt drive and a lead screw. Some of these core considerations include load, orientation, travel length, speed, precision, and environmental conditions. Precision can be further broken down into accuracy and repeatability. Accuracy is a measure of how close to a desired end point the assembly can move a load within a given tolerance. Repeatability, on the other hand, is a measure of how well a driven assembly can repeatedly move a load to the same position.

Cost is a factor as well, but can hinge on how the actuator is being used in an application. In other words, there may be more than just the up-front costs involved. For example, a drive system may require more long-term maintenance, or a harsh application may reduce the overall lifespan of the actuator. With these factors in mind, a proper evaluation of your application and its needs should be assessed in order to choose the most ideal actuator system.

Belt drives and their applications

A belt-driven actuator converts rotary motion into linear motion using a timing belt. The timing belt contains teeth that lock onto toothed pulleys, applying torque and preventing slippage. Often, the belt drive is enclosed within a protective case, and attached to a carriage. The driveshaft and motor are often situated perpendicular to either side of the actuator (horizontal motor mount), or perpendicular to the top of the actuator (vertical motor mount). The PROs and CONs for the use of belt drives, with respect to the application needs, includes:

PROs

- Long strokes. Typically up to 6 meters. Optimal for shuttle transport and material handling applications.

- High linear travel speed. Typically up to 3 – 5 m/sec for long travel distances.

- Higher efficiency. Typically 90-percent. Benefits high-speed and continuous power applications.

- Lower input RPM versus screw drives.

- Higher duty cycles. Continuous duty.

CONs

- Higher cost. Additional costs in vertical applications can be incurred due to gear reducer and motor fail-safe brake requirements, and the need for more input torque from motors.

- Lower accuracy and positional repeatability versus screw drives.

- Velocity ripple. Cogging effect inherent with belts and pulleys.

- More input torque required versus screw drives. Typically requires additional expense of gear reducer.

- Back drive (load drift) will prevail due to high efficiency. Typically requires gear reducers or fail-safe brake motors for load drift prevention in vertical applications.

- Belt retensioning may require preventative periodic adjustments.

- Belt materials that can be adversely affected by corrosive environments.

- Short stroke can cause a belt to take a set to the pulley diameter and always wear on the same portion of belt.

Lead screw drives and their applications

A lead screw uses a threaded rod to translate its rotational motion into linear motion. There are two versions, captive and non-captive, with both options incorporating a compact and simple design that offers smooth and quiet motion. Both options have various screw leads and diameters that can be selected based on the needs of the application. Short leads offer more precision, while long leads will create more speed, and larger diameters offer more rigidity to actuator systems. The PROs and CONs for the use of lead screw drives, with respect to the application needs, includes:

PROs

- Lower cost compared to belt drives.

- Higher accuracy and positional repeatability versus belt drives. Lead screw offers high precision accuracy in applications like medical pipette dispensing, pick-and-place systems, and syringe pumps. Anti-backlash nuts improve positional repeatability and reduce backlash in these types of applications.

- Large range of diameters (6 mm – 16 mm) or (3/16” – 1/2”) with several leads available to match application requirements.

- Quick response in short stroke applications. Lead screw possesses agile acceleration and deceleration rates, and a quicker response than belt drive. An aggressive lead screw can be as fast as a belt drive for strokes less than 500 mm.

- Self-lubing polymer nuts with acetal PTFE composition offer reduced preventative maintenance.

- Smoother and quieter linear motion.

- Lightweight polymer nuts have less nut mass to move.

- Non-corrosive materials. Less susceptible to contamination. A big advantage with PBC linear lead screws is the self-lubricating PTFE coated screw and PTFE composition nut that allows for total immersion in water or other fluids, benefitting most wash-down environments.

- Self-locking eliminates load drift issues in vertical applications when screw efficiency rating is below 35-percent or the screw lead is less than one-third the screw diameter.

- Short stroke polymer nut ideal for this type of application. Short stroke has little to no effect on nut wear.

- Light load, high duty cycle applications benefit applications such as 3D printing.

- Non-captive lead screw configurations not subject to critical speed limitations due to the length of the lead screw.

CONs

- Limited load capacities due to polymer nuts and anti-backlash nut styles.

- Limited speed. Typically <= 1,000 rpm. This limit can be exceeded for lighter payloads. Reference the PBC linear lead screw catalog. Pressure velocity (PV) load derate factors for polymer lead screw nuts should be evaluated for specific application load criteria.

- Limited screw accuracies are available. (PBC linear is best in marketplace at <=0.003” /ft. Competition is typically <=.008”/ft.)

- Not recommended for applications requiring the combination of high load, high speed and continuous duty. Ambient and friction generated heat are primary concerns.