PBC Linear offers product solutions no matter what environmental forces may be causing you problems. Check out what products can help you excel!

If you wish to order a product or request a quote, you may send your inquiry via the form on the website or contact us at info@pbclinear.eu

Maintenance-Free and Durable Assemblies and Components

Bottling and packaging systems must run efficiently, reliably, and without interruptions. PBC Linear offers a full selection of corrosion and chemical resistant linear motion components in the RST, CRT, and GST product families that minimize cracks and crevices, reduce maintenance and prevent bacteria growth.

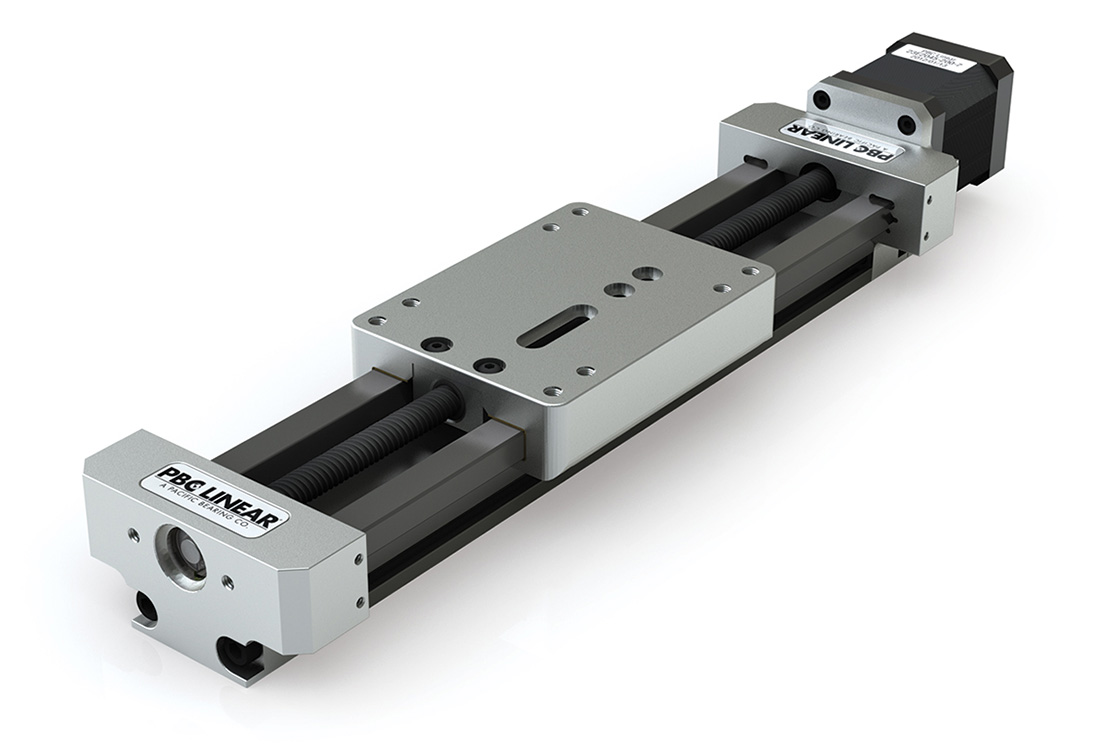

The SIMO® Series enables multiple application requirements to be met with a single platform. Flexible with a uniform geometry as a base with a large number of selectable options in the basic design, drive type and type of guide. The mix and match platform within the same design environment allows configurations to be easily and quickly adjusted.

PROBLEM:

A bottling system required a linear motion solution that could tolerate hig moment loads as well as provide thrust loads.

THE PBC LINEAR SOLUTION:

The SIMO Series is ideal in bottling and food service applications that require repeatable motion and involve various load capacities. Plain bearings utilize the bonded FrelonGold® self-lubricating maintenance-free surface.

KEY BENIFITS:

PBC Linear manufactures Gliding Surface Technology to perform and to withstand harsh environments while offering additional advantages. By utilizing plain bearing design, Gliding Surface Technology offers lower profiles, compact sizes, and smooth, quiet linear motion. Available options and product capabilities provide unlimited design alternatives and configurations.

VISION, SENSORS, SCANNING:

GST rail and carriages provide consistent smooth performance in vision applications due to not having any metal-to-metal contact.

KEY BENIFITS:

Round Shaft Technology utilizes precision round shafting as the guideway and linear plain bearings for movement. RST self-lubricating linear plain bearings come in a wide variety of configurations and offer solutions for a broad range of applications. Open bearings flanged bearings and pillow blocks offer a variety of mounting configurations.

PROBLEM:

A bottling equipment manufacturer was disappointed with ball bearing performance in their automation washdown environments.

THE PBC LINEAR SOLUTION:

Simplicity® plain bearings were used as an effective alternative to ball bearings. The plain bearing Frelon® liners produce a microscopic transfer of thin film that creates a smooth interaction between the bearing and shaft. This in turn allows for the self-lubricating condition of Frelon riding on Frelon. Simplicity bearing are also engineered to wipe particles from shafts, so no seals were needed. Frequent seizing of the bearing and shaft was eliminated.

KEY BENIFITS:

PBC Linear offers product solutions no matter what environmental forces may be causing you problems. Check out what products can help you excel!

Simplicity® plain bearings were used as an effective alternative to ball bearings. The plain bearing Frelon® liners produce a microscopic transfer of thin film that creates a smooth interaction between the bearing and shaft.